Mixers

High Speed Mixer

HIGH SPEED MIXER Hydraulic Lifting & Inverter Controiled Variable Speed

MODEL : HMB-2010E

Standard type

MODEL : HMB-505EC

With Arm Clamper type

MODEL : HMB-2010EF

Flame Proof type

MODEL : HMB-3020ECF

Flame Proof & Arm Clamper type

Applications:

Paints, Inks, Pigments, PU Resin, Silicon glues, Cosmetics, Foodstuff, Ointment...etc mid-viscosity dispersion. Viscosity available under 10,000 cps.

Characteristics:

- Sturdy design base offers vibration free operation. Inverter controlled variable speed motor make the mixer run in step-less speeds for best and optimal mixing speeds from 0-1500rpm.

- Integrated main mechanical body with electric controlled system and hydraulic lifting controlled system in one box to make operations hassle-free. the upper part can be adjustable to match the different mixing angle requirements.

Model Explanation :

- HMB-E : Standard type

- HMB-EC : With Arm Clamper type

- HMB-EF : Flame Proof type

- HMB-ECF : Flame Proof & Arm Clamper type

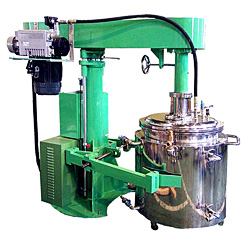

VACUUM TYPE MIXER Hydraulic Lifting & Controlled Variable Speed

Characteristics:

- Main structure is the same as standard type high speed mixer.

To add vacuum pump & vacuum lid for vacuum system. Machine with arm clamper to hold the tank. - Uses concealed hydraulic lifting system to move the mixing shaft up and down. Sturdy design base offers vibration free operation.

Inverter and motor controlled variable speed from 0-1500rpm.

If machine will mix higher viscosity, to add 1:10 reducer and oblique impeller for running variable speed 0-150rpm. - Integrated main mechanical body with electric controlled system and hydraulic lifting controlled system in one box makes operations hassle-free. The upper part can be adjustable to match the different mixing angle requirements. Add the upper vacuum lid with view window, vacuum gauge, filling hole for raw materials, fixed clamper, mixing drum needs to made accordingly with vacuum lid for closing well.

- The mixing drum can do as dual jacket type for either heating or cooling system.

MODEL : HMB-2010ECV

MODEL : HMB-2010ECV

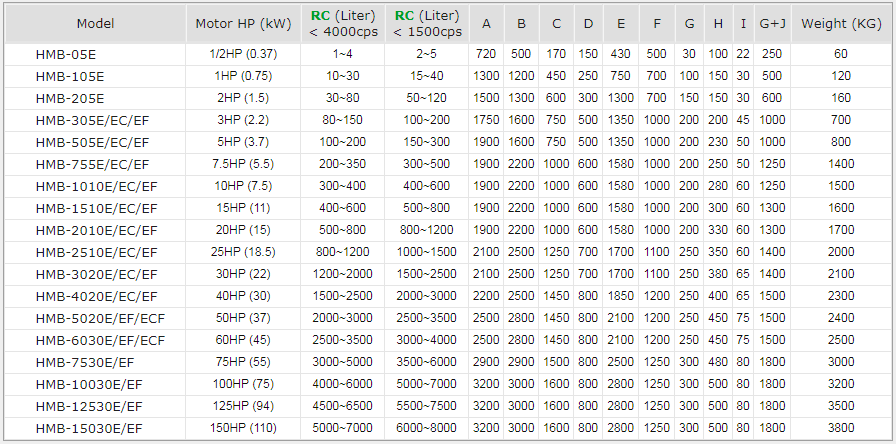

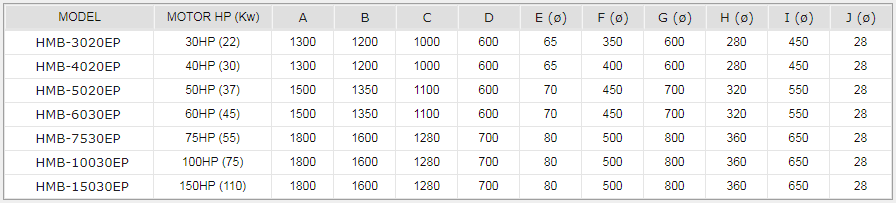

Specifications

RC= (Resolution Capaciyt.) Units : mm

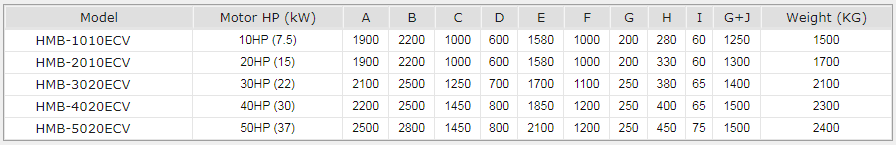

Vacuum Type Mixer

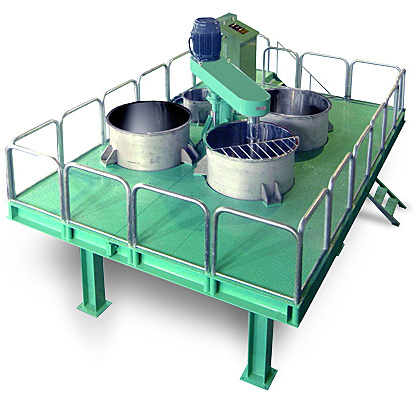

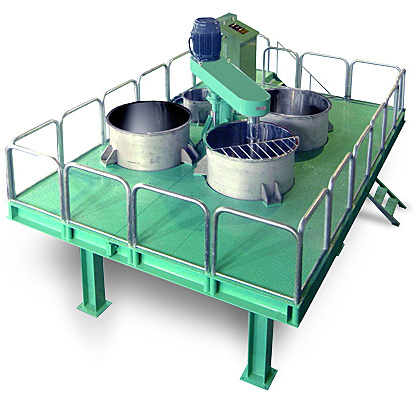

Platform Type High Speed Mixer

PLATFORM TYPE HIGH SPEED MIXER Hydraulic Lifting & Inverter Controiled Variable Speed

Applications:

Paints, Inks, Pigments, PU Resin, Silicon glues, Cosmetics, Foodstuff, Ointment...etc mid-viscosity dispersion. Viscosity available under 10,000 cps.

Characteristics:

- Aim at workflow convenience and volume production. We develop this platform type high speed mixer & dissolver from the same construction of standard high speed mixers. The base of high speed mixer is placed on the platform for easily filling up the raw materials. The finished products can be drained for packing or next producing process easily.

- Inverter controls variable speed from 0 to 1,500rpm. Any speed can be set for best and optimal mixing results. The upper arm can swivel freely for changing the drum. It suits for multiple mixing drums and discharge systems. Hydraulic lifting up/down systems.

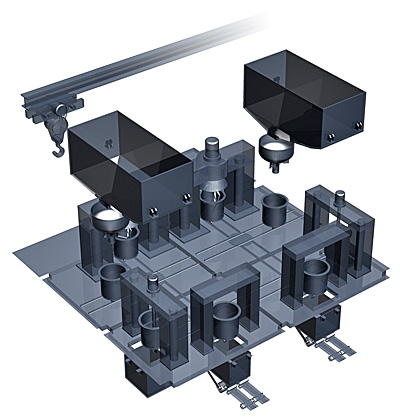

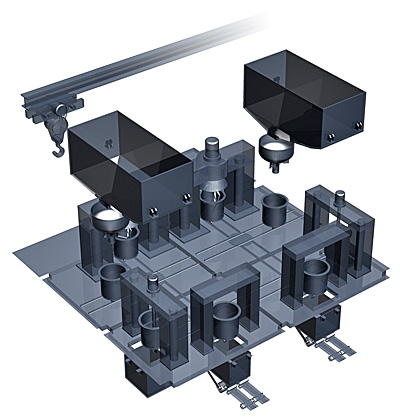

Platform Type Mixer - Three Processes Steel Formwork

The overall device structure is designed to triple steel formwork, and the ground plane a total of four, the top four as the raw material storage area, and the third layer of material measurement scale area, the second layer mixing operation area, stirring to complete the unloading and then dumped Tu cream machine storage tank, then painted cream machine, screw conveyor transported to storage tanks painted cream machine hopper ground storage tanks.

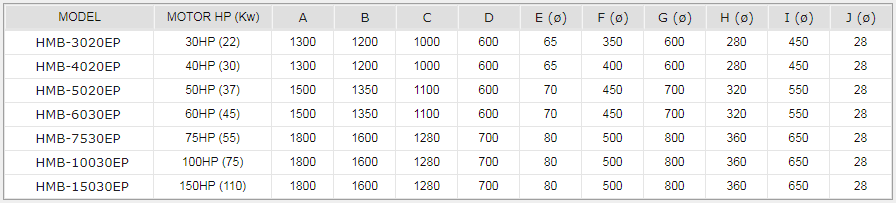

Specifications

Units : mm

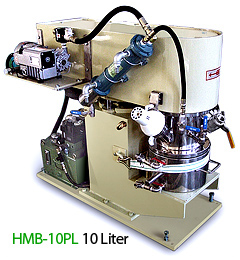

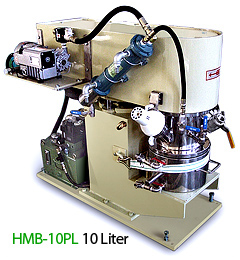

HIGH VISCOSITY TWIN OAK IMPELLER PLANETARY MIXER Vacuum Type

MODEL : HMB-20PL

MODEL : HMB-100PL

MODEL : HMB-500PL

MODEL : HMB-2000PL

Applications:

Paints, Inks, Pigments, PU Resin, Silicon glues, Cosmetics, Foodstuff, Ointment...etc High viscosity dispersion.

Characteristics:

- Planetary type revolving and rotation mixer uses gears transmission to drive two impellers rotating in the same directions, producing the interactive kneading, twisting and dispersing effects. Besides the interactive rotations, the both impellers can revolving around the mixing tank and bring the materials inside for complete mixing.

The vacuum mixing environments make the high viscosity materials to disperse & homogenize completely in tank.This mixer is suitable for viscosity : 200,000 cps - Twin shafts rotation speeds : 0~200rpm

- Revolving speed : 0~40rpm

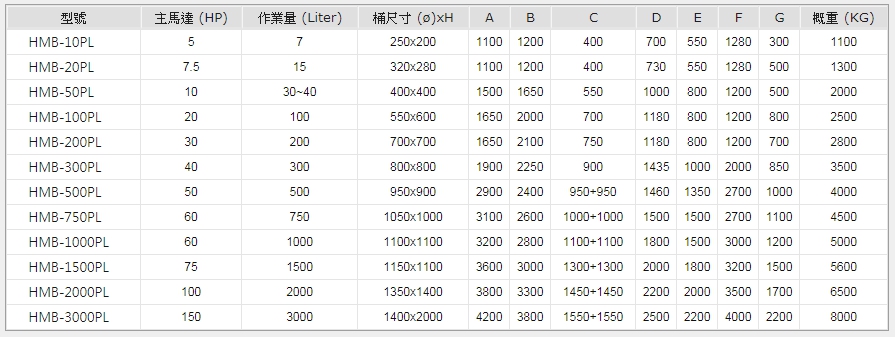

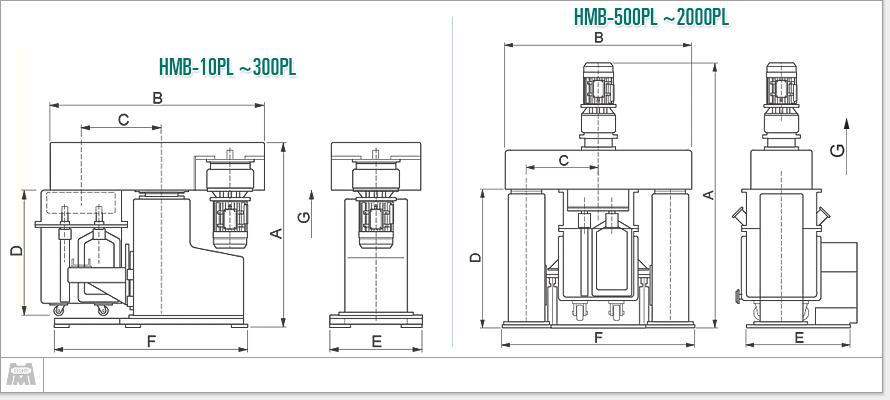

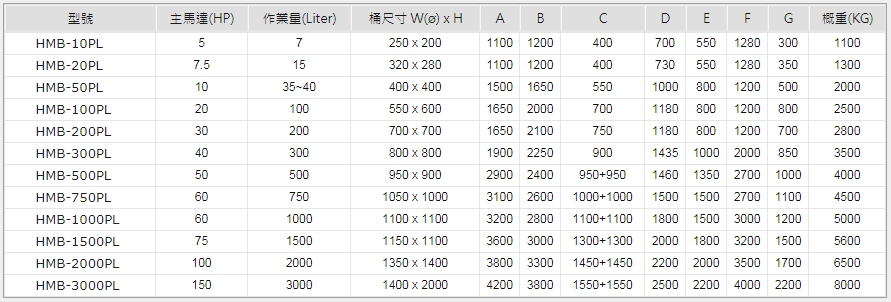

Specifications

RC= (Resolution Capaciyt.) Units : mm

HIGH VISCOSITY THREE SHAFTS MIXER Vacuum Type

MODEL : HMB-100T

MODEL : HMB-200T

MODEL : HMB-500T

MODEL : HMB-3000T

Applications:

Paints, Inks, Pigments, PU Resin, Silicon glues, Cosmetics, Foodstuff, Ointment... etc High viscosity dispersion.

Characteristics:

- The three shafts high viscosity mixer was designed for low floating nature and high viscosity materials. The central anchor impeller equips with scraper blades for removing adhered materials from the sides and bottom of the mixing tanks. The two serrated rotating in high speeds producing kneading, twisting and dispersing effects. While in the mixing process, the two serrated impeller will produce two whirlpools and the central anchor impeller will create turbulences which make the low floating nature materials achieve high efficiency blending, dispersing and mixing effects.

- This mixer is suitable for viscosity 30,000-200,000cps without heating system.

With optional heating system this mixer is suitable for viscosity 500,000cps. - Central Anchor low speed shaft: 0-30rpm. Two serrated high speed shafts: 0-1500rpm.

Specifications

RC= (Resolution Capaciyt.) Units : mm

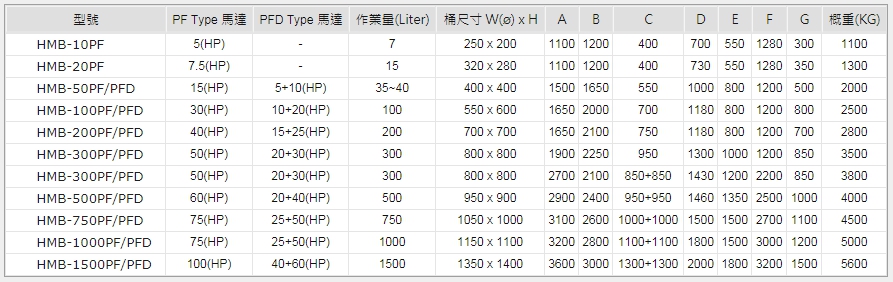

FOUR SHAFTS HIGH VISCOSITY PLANETARY MIXER Vacuum Type

Single Motor

MODEL : HMB-10PF

MODEL : HMB-200PF

MODEL : HMB-300PF

MODEL : HMB-500PF

Two Motor

MODEL : HMB-50PFD

MODEL : HMB-100PFD

MODEL : HMB-300PFD

MODEL : HMB-300PFD

Applications:

Paints, Inks, Pigments, PU Resin, Silicon glues, Putty, Sealants, Foodstuff, Dyestuffs, Ointments, Cosmetics... etc high viscosity dispersion.

Characteristics:

- The four shaft high viscosity planetary mixer uses gears transmission to drive two low speed impellers rotating in the same directions, It makes the interactive kneading, twisting and dispersing effects. Two serrated disc shafts drives by variable high speed. Two oak impellers shafts drives by variable low speed. While mixing, two high speed shafts will make two high speed whirlpools, two low speed shafts will make turbulences, the planetary revolving speed will make another circulation. Those circulations come cross to make the best kneading, twisting and dispersing effects for raw materials in tank.

- Vacuum lid assembles on upper shaft, lid has two view windows, one illumination light, one vacuum gauge, one filling hole, one hole for discharging air, one hole for drawing air.

- The parts which will touching the raw material are made of #304 stainless steel.

- Machine designs the interlock to hold the tank while mixing.

- Safety design :

(a) When vacuum lid lifts up and apart from mixing tank, the machine will stop mixing automatically.

(b)When machine has overload running or over viscosity running, the machine will stop operating automatically. - This mixer is available for viscosity 30,000-200,000cps without heating system.

With optional heating system this mixer is suitable for viscosity 500,000cps. - Two motors has the same structures with single motor, the difference is that the planetary of rotation and revolution uses one motor to drive two variable speed, and the high speed shaft uses another motor to drive.

Those three speeds can be done as variable speed according to the mixing requirement. - (A) Planetary revolving speed : 0~40rpm (B) Two low speed impeller : 0~200rpm (C) Two high speed serrated discs impeller : 0~1500rpm

Specifications

RC= (Resolution Capaciyt.) Units : mm

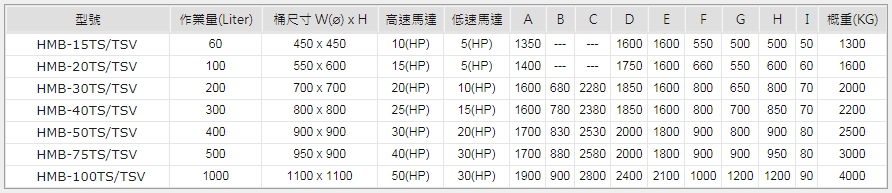

HIGH VISCOSITY BUTTERFLY TWIN SHAFTS MIXER Stand & Vacuum Type

MODEL : HMB-TS STANDARD TYPE

MODEL : HMB-TSV VACUUM TYPE

Applications:

Paints, Inks, Pigments, PU Resin, Silicon glues, Foodstuff, Dyestuffs, Ointments, Cosmetic... etc high viscosity dispersion.

Characteristics:

- Butterfly two shafts mixer aims at thick and high viscosity liquid materials. The central low speed designs the butterfly type impeller with Teflon scrapers, Teflon scraper can remove the adhered material which mass on inside tank wall and inside tank bottom into the mixing circulation for completely mixing. Mixing shaft can lift up and down for better mixing quality. One high speed shaft will make one high speed whirlpools, one low speed shaft will make another circulation, Those circulations come cross to make the best kneading twisting and dispersing effects for raw materials in tank.

- The parts which will touching the raw material are made of #304 stainless steel.

- Machine designs the arm holder to fix the tank while mixing.

- High speed serrate impeller runs from 0~1500rpm, Low speed butterfly impeller runs from 0~60rpm.

- Available viscosity 100.,000cps.

- TS TYPE STANDARD TYPE TSV TYPE VACUUM TYPE

Specifications

RC= (Resolution Capaciyt.) Units : mm

HOMOCENTRIC SHAFTS HIGH VISCOSITY MIXER

Applications:

Paints, Inks, Pigments, PU Resin, Silicon glues, Foodstuff, Dyestuffs, Ointments, Cosmetic... etc high viscosity dispersion.

Characteristics:

- Single homocentric shaft with high speed impeller and low speed impeller, hydraulic up/down system.

- High speed impeller can assemble the serrate disc or high speed emulsifiable implement. Individual motor with inverter to control the variable high speed 0-1500rpm or 0-3000rpm.

- Low speed impeller equips with Teflon scrapers to remove adhered materials from the sides of the mixing tanks for completely dispersion.

Motor with 1:30 reducer and inverter to control the variable speed from 0~60rpm. - High viscosity product uses complete piece of Teflon scraper to scrape whole tank wall.

Mid-viscosity product uses disconnected piece of Teflon scraper to save the electric power. - HC TYPE STANDARD TYPE

HCV TYPE VACUUM TYPE

High Speed Mixer

HIGH SPEED MIXER Hydraulic Lifting & Inverter Controiled Variable Speed

MODEL : HMB-2010E

Standard type

MODEL : HMB-505EC

With Arm Clamper type

MODEL : HMB-2010EF

Flame Proof type

MODEL : HMB-3020ECF

Flame Proof & Arm Clamper type

Applications:

Paints, Inks, Pigments, PU Resin, Silicon glues, Cosmetics, Foodstuff, Ointment...etc mid-viscosity dispersion. Viscosity available under 10,000 cps.

Characteristics:

- Sturdy design base offers vibration free operation. Inverter controlled variable speed motor make the mixer run in step-less speeds for best and optimal mixing speeds from 0-1500rpm.

- Integrated main mechanical body with electric controlled system and hydraulic lifting controlled system in one box to make operations hassle-free. the upper part can be adjustable to match the different mixing angle requirements.

Model Explanation :

- HMB-E : Standard type

- HMB-EC : With Arm Clamper type

- HMB-EF : Flame Proof type

- HMB-ECF : Flame Proof & Arm Clamper type

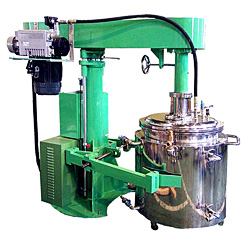

VACUUM TYPE MIXER Hydraulic Lifting & Controlled Variable Speed

Characteristics:

- Main structure is the same as standard type high speed mixer.

To add vacuum pump & vacuum lid for vacuum system. Machine with arm clamper to hold the tank. - Uses concealed hydraulic lifting system to move the mixing shaft up and down. Sturdy design base offers vibration free operation.

Inverter and motor controlled variable speed from 0-1500rpm.

If machine will mix higher viscosity, to add 1:10 reducer and oblique impeller for running variable speed 0-150rpm. - Integrated main mechanical body with electric controlled system and hydraulic lifting controlled system in one box makes operations hassle-free. The upper part can be adjustable to match the different mixing angle requirements. Add the upper vacuum lid with view window, vacuum gauge, filling hole for raw materials, fixed clamper, mixing drum needs to made accordingly with vacuum lid for closing well.

- The mixing drum can do as dual jacket type for either heating or cooling system.

MODEL : HMB-2010ECV

MODEL : HMB-2010ECV

Specifications

RC= (Resolution Capaciyt.) Units : mm

Vacuum Type Mixer

Platform Type High Speed Mixer

PLATFORM TYPE HIGH SPEED MIXER Hydraulic Lifting & Inverter Controiled Variable Speed

Applications:

Paints, Inks, Pigments, PU Resin, Silicon glues, Cosmetics, Foodstuff, Ointment...etc mid-viscosity dispersion. Viscosity available under 10,000 cps.

Characteristics:

- Aim at workflow convenience and volume production. We develop this platform type high speed mixer & dissolver from the same construction of standard high speed mixers. The base of high speed mixer is placed on the platform for easily filling up the raw materials. The finished products can be drained for packing or next producing process easily.

- Inverter controls variable speed from 0 to 1,500rpm. Any speed can be set for best and optimal mixing results. The upper arm can swivel freely for changing the drum. It suits for multiple mixing drums and discharge systems. Hydraulic lifting up/down systems.

Platform Type Mixer - Three Processes Steel Formwork

The overall device structure is designed to triple steel formwork, and the ground plane a total of four, the top four as the raw material storage area, and the third layer of material measurement scale area, the second layer mixing operation area, stirring to complete the unloading and then dumped Tu cream machine storage tank, then painted cream machine, screw conveyor transported to storage tanks painted cream machine hopper ground storage tanks.

Specifications

Units : mm

HIGH VISCOSITY TWIN OAK IMPELLER PLANETARY MIXER Vacuum Type

MODEL : HMB-20PL

MODEL : HMB-100PL

MODEL : HMB-500PL

MODEL : HMB-2000PL

Applications:

Paints, Inks, Pigments, PU Resin, Silicon glues, Cosmetics, Foodstuff, Ointment...etc High viscosity dispersion.

Characteristics:

- Planetary type revolving and rotation mixer uses gears transmission to drive two impellers rotating in the same directions, producing the interactive kneading, twisting and dispersing effects. Besides the interactive rotations, the both impellers can revolving around the mixing tank and bring the materials inside for complete mixing.

The vacuum mixing environments make the high viscosity materials to disperse & homogenize completely in tank.This mixer is suitable for viscosity : 200,000 cps - Twin shafts rotation speeds : 0~200rpm

- Revolving speed : 0~40rpm

Specifications

RC= (Resolution Capaciyt.) Units : mm

HIGH VISCOSITY THREE SHAFTS MIXER Vacuum Type

MODEL : HMB-100T

MODEL : HMB-200T

MODEL : HMB-500T

MODEL : HMB-3000T

Applications:

Paints, Inks, Pigments, PU Resin, Silicon glues, Cosmetics, Foodstuff, Ointment... etc High viscosity dispersion.

Characteristics:

- The three shafts high viscosity mixer was designed for low floating nature and high viscosity materials. The central anchor impeller equips with scraper blades for removing adhered materials from the sides and bottom of the mixing tanks. The two serrated rotating in high speeds producing kneading, twisting and dispersing effects. While in the mixing process, the two serrated impeller will produce two whirlpools and the central anchor impeller will create turbulences which make the low floating nature materials achieve high efficiency blending, dispersing and mixing effects.

- This mixer is suitable for viscosity 30,000-200,000cps without heating system.

With optional heating system this mixer is suitable for viscosity 500,000cps. - Central Anchor low speed shaft: 0-30rpm. Two serrated high speed shafts: 0-1500rpm.

Specifications

RC= (Resolution Capaciyt.) Units : mm

FOUR SHAFTS HIGH VISCOSITY PLANETARY MIXER Vacuum Type

Single Motor

MODEL : HMB-10PF

MODEL : HMB-200PF

MODEL : HMB-300PF

MODEL : HMB-500PF

Two Motor

MODEL : HMB-50PFD

MODEL : HMB-100PFD

MODEL : HMB-300PFD

MODEL : HMB-300PFD

Applications:

Paints, Inks, Pigments, PU Resin, Silicon glues, Putty, Sealants, Foodstuff, Dyestuffs, Ointments, Cosmetics... etc high viscosity dispersion.

Characteristics:

- The four shaft high viscosity planetary mixer uses gears transmission to drive two low speed impellers rotating in the same directions, It makes the interactive kneading, twisting and dispersing effects. Two serrated disc shafts drives by variable high speed. Two oak impellers shafts drives by variable low speed. While mixing, two high speed shafts will make two high speed whirlpools, two low speed shafts will make turbulences, the planetary revolving speed will make another circulation. Those circulations come cross to make the best kneading, twisting and dispersing effects for raw materials in tank.

- Vacuum lid assembles on upper shaft, lid has two view windows, one illumination light, one vacuum gauge, one filling hole, one hole for discharging air, one hole for drawing air.

- The parts which will touching the raw material are made of #304 stainless steel.

- Machine designs the interlock to hold the tank while mixing.

- Safety design :

(a) When vacuum lid lifts up and apart from mixing tank, the machine will stop mixing automatically.

(b)When machine has overload running or over viscosity running, the machine will stop operating automatically. - This mixer is available for viscosity 30,000-200,000cps without heating system.

With optional heating system this mixer is suitable for viscosity 500,000cps. - Two motors has the same structures with single motor, the difference is that the planetary of rotation and revolution uses one motor to drive two variable speed, and the high speed shaft uses another motor to drive.

Those three speeds can be done as variable speed according to the mixing requirement. - (A) Planetary revolving speed : 0~40rpm (B) Two low speed impeller : 0~200rpm (C) Two high speed serrated discs impeller : 0~1500rpm

Specifications

RC= (Resolution Capaciyt.) Units : mm

HIGH VISCOSITY BUTTERFLY TWIN SHAFTS MIXER Stand & Vacuum Type

MODEL : HMB-TS STANDARD TYPE

MODEL : HMB-TSV VACUUM TYPE

Applications:

Paints, Inks, Pigments, PU Resin, Silicon glues, Foodstuff, Dyestuffs, Ointments, Cosmetic... etc high viscosity dispersion.

Characteristics:

- Butterfly two shafts mixer aims at thick and high viscosity liquid materials. The central low speed designs the butterfly type impeller with Teflon scrapers, Teflon scraper can remove the adhered material which mass on inside tank wall and inside tank bottom into the mixing circulation for completely mixing. Mixing shaft can lift up and down for better mixing quality. One high speed shaft will make one high speed whirlpools, one low speed shaft will make another circulation, Those circulations come cross to make the best kneading twisting and dispersing effects for raw materials in tank.

- The parts which will touching the raw material are made of #304 stainless steel.

- Machine designs the arm holder to fix the tank while mixing.

- High speed serrate impeller runs from 0~1500rpm, Low speed butterfly impeller runs from 0~60rpm.

- Available viscosity 100.,000cps.

- TS TYPE STANDARD TYPE TSV TYPE VACUUM TYPE

Specifications

RC= (Resolution Capaciyt.) Units : mm

HOMOCENTRIC SHAFTS HIGH VISCOSITY MIXER

Applications:

Paints, Inks, Pigments, PU Resin, Silicon glues, Foodstuff, Dyestuffs, Ointments, Cosmetic... etc high viscosity dispersion.

Characteristics:

- Single homocentric shaft with high speed impeller and low speed impeller, hydraulic up/down system.

- High speed impeller can assemble the serrate disc or high speed emulsifiable implement. Individual motor with inverter to control the variable high speed 0-1500rpm or 0-3000rpm.

- Low speed impeller equips with Teflon scrapers to remove adhered materials from the sides of the mixing tanks for completely dispersion.

Motor with 1:30 reducer and inverter to control the variable speed from 0~60rpm. - High viscosity product uses complete piece of Teflon scraper to scrape whole tank wall.

Mid-viscosity product uses disconnected piece of Teflon scraper to save the electric power. - HC TYPE STANDARD TYPE

HCV TYPE VACUUM TYPE